Home > Products > Product Series > Voltage classification > High voltage permanent magnet synchronous motor >TYWFG series 10...

This series of products has a rated voltage of 10KV and a power range of 280KW-5000KW, and is controlled and regulated by frequency converter.

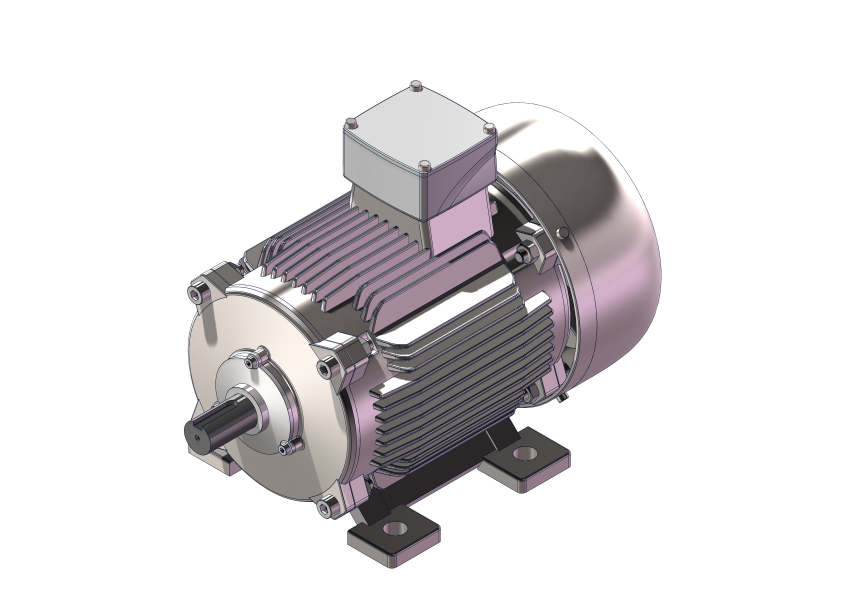

This series of products is based on the frame size design of the original high-voltage asynchronous motor, which can completely replace Y, YKK, YKS, YRKK and other series of high-voltage asynchronous motors.

High efficiency and power factor, good starting torque performance, low noise, small vibration, safe and reliable operation, high efficiency and energy saving, and obvious energy saving effect. Under working conditions, the power saving rate is 10%-20%.

The efficiency index of this series of products exceeds the highest energy efficiency level 1 of GB18613-2020 "Energy Efficiency Allowable Values and Energy Efficiency Grades of Electric Motors" efficiency value.

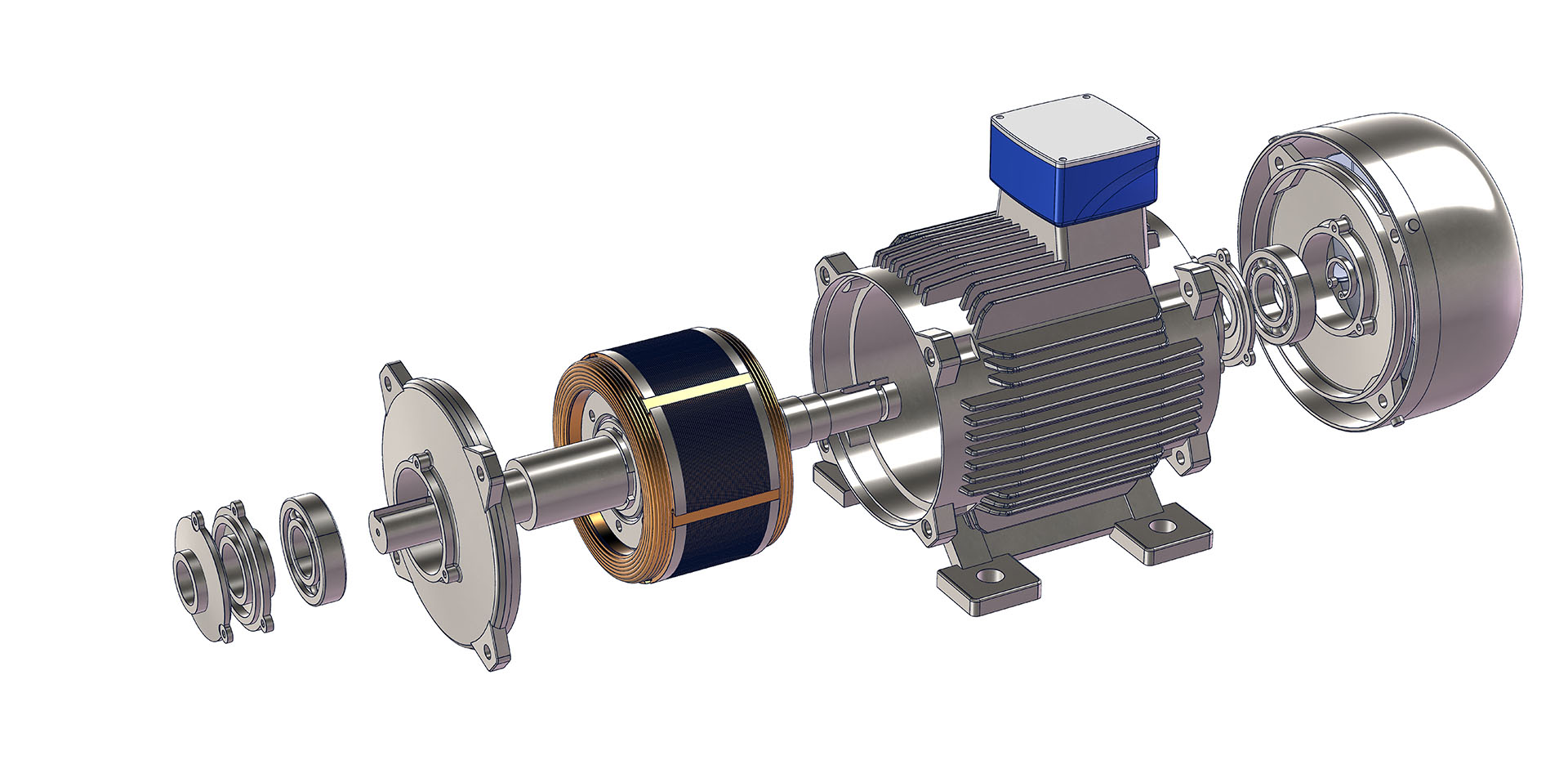

This series adopts a circular base design, adopts axial flow or centrifugal surface heat dissipation to force cooling, and reduces the size of the motor The volume is smaller, and the air-air and air-water cooling methods of the traditional high-voltage motor are removed, the structure is simple, and the maintenance is convenient.

Protection grade IP54, F-class insulation, S1 working system. It has a novel design (simple installation design according to the site installation environment and equipment supporting conditions), compact structure, beautiful appearance, high efficiency and power factor, good starting torque performance, low noise, small vibration, safe and reliable operation, high efficiency and energy saving.

The rated voltage of this series of products is 10KV, and the power range is 280KW-5000KW. The motor is controlled and adjusted by a frequency converter, with stable start and stop, strong protection performance, intelligent control, and a wide frequency adjustment range to better achieve energy-saving effects. In the range of 25%-120% load, this series of products has higher efficiency than asynchronous motors of the same specification, a wider economical operating range, and significant energy-saving effects.

The temperature rise of the motor is low. Under the rated load, the temperature rise of the motor is 40-60K. This series of products can completely replace Y, YKK, YKS and other series of high-voltage asynchronous motors.

This series of products are widely used in electric power, water source treatment, petroleum, chemical industry, building materials, metallurgy, mining and other industries for Drive various production machinery.

Permanent magnet synchronous motor provides the magnetic field required for electromechanical energy conversion by permanent magnets, without excitation power supply. There is almost no current in the rotor during synchronous operation, so the copper loss of the rotor is close to zero, and the power factor is greatly improved compared with the asynchronous motor. The reactive current in the stator winding is small, the copper loss of the stator is reduced, and the efficiency of the permanent magnet synchronous motor is higher than that of the asynchronous motor under the same conditions. The actual operating current of the permanent magnet synchronous motor is more than 15% lower than that of the asynchronous motor. The temperature rise is about 20K lower than that of a three-phase asynchronous motor with the same power and speed, and the power factor reaches 0.96 or above. The rated efficiency is 1% to 8% higher than that of the three-phase asynchronous motor, and the efficiency index The efficiency exceeds GB18613-2020 "Motor Energy Efficiency Limits and Energy Efficiency Class >>The efficiency value of the highest energy efficiency class 1.

Permanent magnet synchronous motors also have significant advantages in other aspects:

1) Synchronous operation, no speed fluctuations, no increase in pipeline resistance when driving fans and pumps ;

2) It can be designed with high starting torque and high overload capacity, so as to solve the phenomenon of "big horse and small car" ;

3) The high-efficiency operating range is wide, and its operating efficiency and power factor are stable when the load rate is 25%-120% The change is small, and the operating efficiency is >85%, the power factor is >0.9, and the energy saving effect is remarkable.

4) The power factor is high, which improves the quality factor of the power grid. There is no need to install reactive power compensation devices in the power grid. The capacity of the substation equipment can be fully utilized.

5) Work with the frequency conversion speed regulation system, compared with the asynchronous motor, the dynamic response is better.

6) High power density, at the same power and speed, it can reduce at least one frame size compared with asynchronous motor .

7) There are many topological structures of permanent magnet synchronous motors, and customized products can be realized in a wide range and under extreme conditions Serve.

| TYWFG series 10KV high voltage motor model and parameters | ||||||||

| model | power (kW) | synchronous speed (r/min) | rated current(A) | efficiency (%) | power factor | Stall current multiple | Stall torque multiple | Maximum torque multiple |

| TYWFG450-6/75 | 355 | 1500 | 21.5 | 95.3 | 0.96 | 9.5 | 1.2 | 1.8 |

| TYWFG450-6/75 | 400 | 24.7 | 95.5 | |||||

| TYWFG450-6/75 | 450 | 27.2 | 95.9 | |||||

| TYWFG450-6/76 | 500 | 30.5 | 96.0 | |||||

| TYWFG450-6/77 | 560 | 34.9 | 96.2 | |||||

| TYWFG450-6/78 | 630 | 38.8 | 96.4 | |||||

| TYWFG500-6/75 | 710 | 44.6 | 97.0 | 0.96 | ||||

| TYWFG500-6/75 | 800 | 50.8 | 97.1 | |||||

| TYWFG500-6/75 | 900 | 56.0 | 97.2 | 0.96 | ||||

| TYWFG500-6/75 | 1000 | 62.8 | 97.3 | |||||

| TYWFG500-6/75 | 1120 | 67.0 | 97.4 | |||||

| TYWFG560-6/75 | 1250 | 74.9 | 97.5 | 0.96 | ||||

| TYWFG560-6/75 | 1400 | 85.9 | 97.7 | |||||

| TYWFG560-6/75 | 1600 | 98.3 | 97.8 | |||||

| TYWFG630-6/75 | 1800 | 111.7 | 97.9 | 1 | ||||

| TYWFG630-6/75 | 2000 | 123.1 | 98.0 | |||||

| TYWFG630-6/75 | 2240 | 138.2 | 98.1 | |||||

| TYWFG450-8/66.6 | 315 | 1000 | 19.9 | 94.8 | 0.96 | 9 | 1 | 1.8 |

| TYWFG450-8/66.7 | 355 | 22.5 | 95.1 | 0.96 | ||||

| TYWFG450-8/66.8 | 400 | 25.8 | 95.3 | |||||

| TYWFG450-8/66.9 | 450 | 28.5 | 95.5 | |||||

| TYWFG500-8/66.6 | 500 | 31.0 | 95.9 | |||||

| TYWFG500-8/66.6 | 560 | 34.9 | 96.1 | 0.94 | ||||

| TYWFG500-8/66.6 | 630 | 38.9 | 96.4 | |||||

| TYWFG500-8/66.6 | 710 | 44.6 | 96.6 | |||||

| TYWFG500-8/66.6 | 800 | 50.1 | 96.7 | 0.94 | 9 | 1 | 1.8 | |

| TYWFG560-8/66.6 | 900 | 56.4 | 96.9 | 0.95 | ||||

| TYWFG560-8/66.6 | 1000 | 61.4 | 97.1 | |||||

| TYWFG560-8/66.6 | 1120 | 69.8 | 97.3 | |||||

| TYWFG560-8/66.6 | 1250 | 77.0 | 97.4 | 0.96 | ||||

| TYWFG630-8/66.6 | 1400 | 87.2 | 97.7 | 1 | ||||

| TYWFG630-8/66.6 | 1600 | 99.1 | 97.8 | |||||

| TYWFG630-8/66.6 | 1800 | 111.0 | 97.9 | |||||

| TYWFG500-8/50 | 315 | 750 | 19.6 | 94.8 | 0.96 | 8.5 | 1 | |

| TYWFG500-8/50 | 355 | 22.6 | 95.1 | |||||