This series of products is a direct-drive permanent magnet synchronous motor. The product is designed according to the equipment requirements and the use environment. The voltage is 380V/6KV/10KV.

This series of products are axial fan/forced air cooling/air-air cooling structure, protection class IP55, class F insulation, S1 working system. According to the needs of users, other protection levels and cooling methods can be provided.

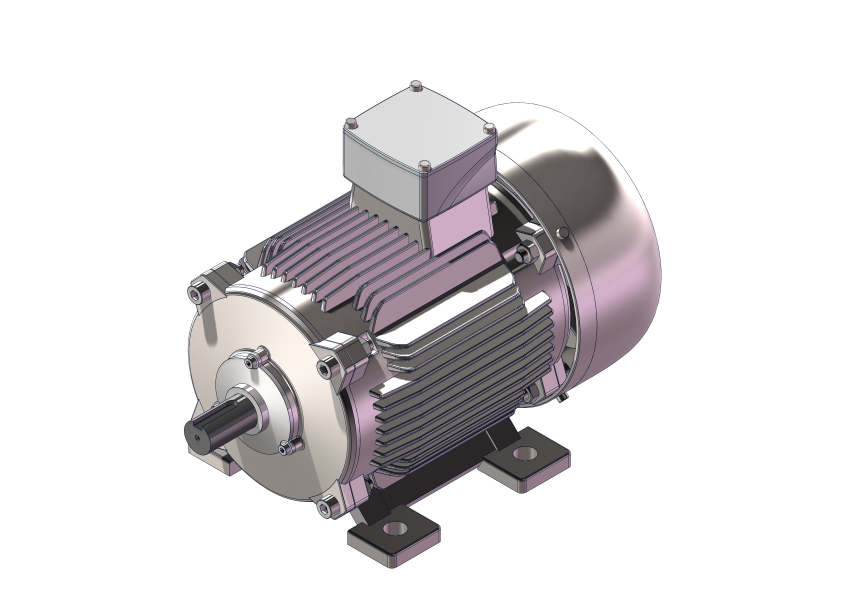

This series of products is a direct-drive motor with a rated voltage of 380V/6KV/10KV, powered by a frequency converter, which can directly meet the requirements of the load speed and torque, and will save The reduction box and the buffer mechanism and other links fundamentally overcome the various disadvantages of the transmission system of the induction motor plus the gear reducer.

The efficiency index of this series of products exceeds the efficiency value of the highest energy efficiency level 1 in GB18613-2020 "Energy Efficiency Limits and Energy Efficiency Grades of Electric Motors", reaching the leading level of similar products.

This series of products is powered by frequency converter, which meets the requirements of load speed and torque, and saves the gear box and buffer mechanism in the transmission system.

This series of products has the advantages of high system transmission efficiency, good starting torque performance, energy saving, extremely low noise, small vibration, low temperature rise, safe and reliable operation, and low installation and maintenance costs.

This series of products fundamentally overcomes various disadvantages of the induction motor + gear reducer transmission system, and directly drives the load equipment.

This series of products are widely used in industrial and mining enterprises such as coal mines, mines, cement, metallurgy, electric power, chemicals, building materials, etc., for driving ball mills, belt conveyors, mixers, hoists, etc.Crushers, filter machines, plastic extruders and other mechanical equipment.

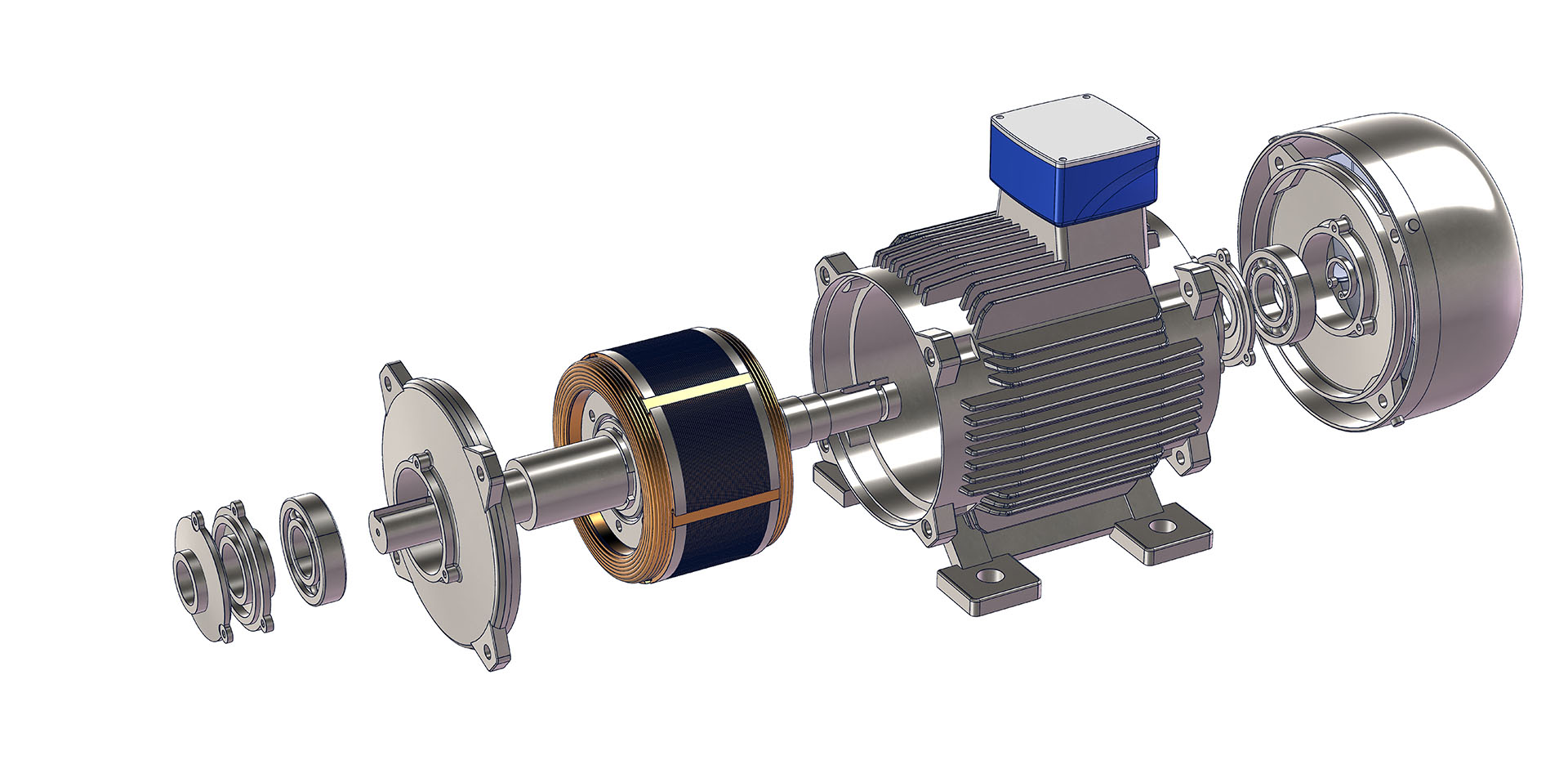

The permanent magnet synchronous motor direct drive system consists of a low-speed high-torque permanent magnet direct drive motor and a dedicated frequency converter for permanent magnet motors. The vector control function of the frequency converter can meet the operating requirements of low-speed equipment. This system replaces the original (inverter) + universal asynchronous motor + (hydraulic coupling) + deceleration mechanism. The permanent magnet synchronous motor is directly connected to the load, which simplifies the transmission chain. The system is realized through the high efficiency of the permanent magnet motor and the improvement of the efficiency of the transmission system. At the same time, the hydraulic coupling and reducer are eliminated, which eliminates the mechanical failure and oil leakage problems that are prone to occur during operation. The program has the following characteristics:

① The transmission chain is shortened, there is no problem of oil leakage and refueling, the mechanical failure rate is low, and the reliability is high.

② Customized electromagnetic design according to equipment conditions. Electromagnetic and structural design can directly meet the speed and torque requirements of the load.

③ The starting current is small and the temperature rise is low, which eliminates the risk of demagnetization.

④ The transmission efficiency loss of the gearbox and hydraulic coupling is eliminated, and the system has high efficiency, high efficiency and energy saving. The structure is simple, the operation noise is small, and the daily maintenance cost is low.

⑤ The rotor part has a special support structure, which can realize on-site replacement of bearings, saves the logistics cost required for returning to the factory, saves maintenance time, and better guarantees the production reliability of users.

⑥ The permanent magnet synchronous motor direct drive system can solve the problem of "big horse-drawn trolley", which not only meets the requirements of the original system for wide load range operation, but also improves the overall efficiency of the system and saves energy.

⑦ It adopts vector frequency converter control, the speed adjustment range is 0-100%, the motor has good starting performance and stable operation, which can reduce the matching coefficient with the actual load power.

| TYWFZQ series rare earth permanent magnet direct drive synchronous motor model and parameter list | ||||||

| The product is specially designed according to the equipment model, use requirements and environmental requirements | ||||||

| Voltage | power | Rotating speed | torque | power factor | Starting torque multiple | Overload multiple |

| 380V | 11KW-315KW | 10rpm-500rpm | 200NM-60000NM | ≥0.96 | ≥2.5 | ≥3.0 |

| 6V | 280KW-315KW | 30rpm-500rpm | 5000NM-100000NM | ≥0.96 | ≥2.5 | ≥3.0 |

| 10V | 280KW-315KW | 30rpm-500rpm | 5000NM-100000NM | ≥0.96 | ≥2.5 | ≥3.0 |

| Conditions of use: ambient temperature: -45°~+65°; relative humidity: ≤90%; altitude: less than or equal to 100m. | ||||||