Latest Policy | Phasing out inefficient and outdated motors, the National Development and Reform Commission issued the implementation guide for motor modernization and recycling (2023 edition)

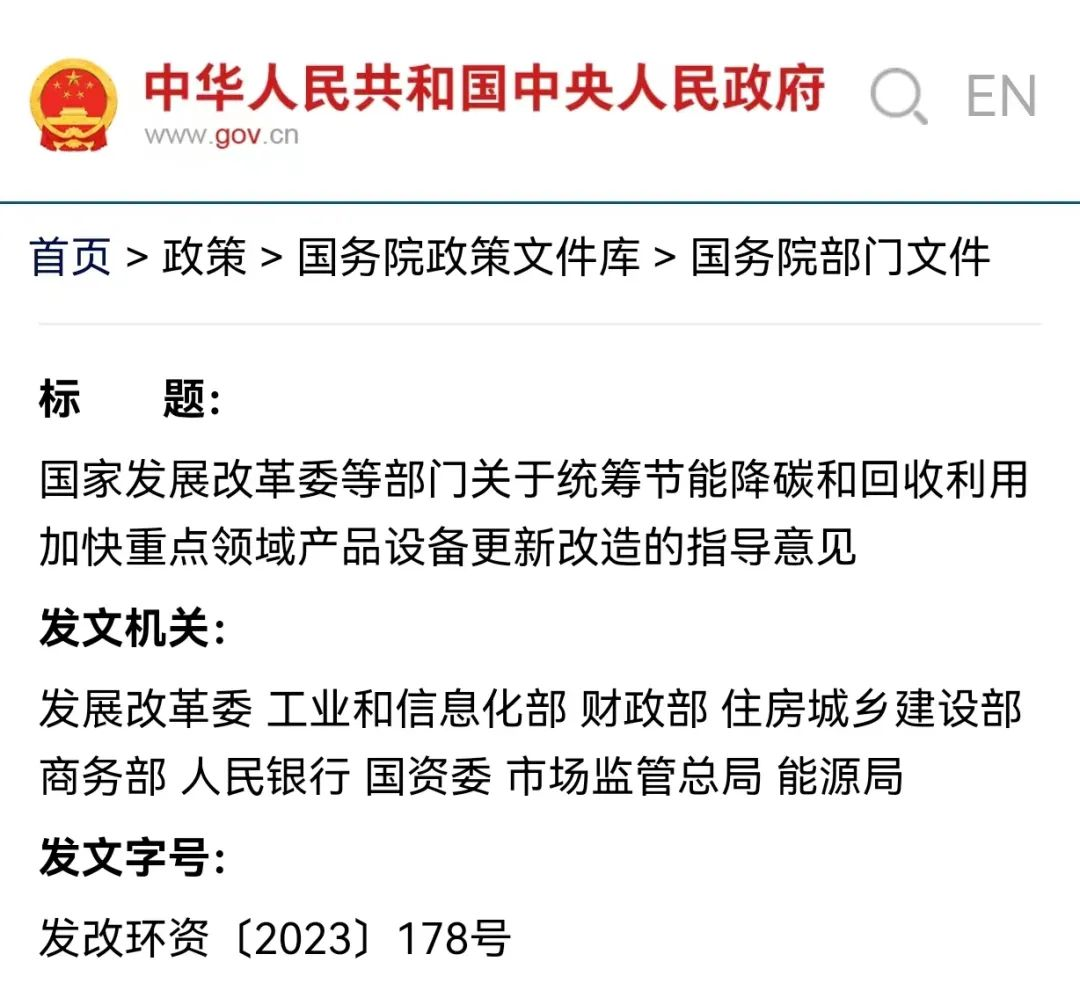

Recently, the National Development and Reform Commission, together with the Ministry of Industry and Information Technology, the Ministry of Finance, the Ministry of Housing and Urban-Rural Development, the Ministry of Commerce, the People's Bank of China, the State-owned Assets Supervision and Administration Commission of the State Council, the State Administration for Market Regulation, the National Energy Administration and other departments, issued the "Guiding Opinions on Coordinating Energy Conservation, Carbon Reduction and Recycling to Accelerate the Renewal and Transformation of Products and Equipment in Key Areas" with Document No. 178 [2023], which is closely related to motor products. The details are as follows.

A guide to the implementation of motor modernization and recycling

(2023 Edition)

First, the basic situation

Motor is an important equipment to realize the conversion of electrical energy and mechanical energy, and is widely used in energy, industry, agriculture, construction, transportation and other fields. According to the statistics of relevant institutions, by the end of 2021, China's motor ownership was about 3 billion kilowatts, and the annual electricity consumption was about 4.5 trillion kilowatt hours, accounting for about 55% of the total electricity consumption of the whole society and 75% of the industrial electricity consumption. Since the "Eleventh Five-Year Plan", China has vigorously promoted high-efficiency and energy-saving motors, promoted the renewal and transformation of existing motors, and steadily improved the energy efficiency level of motors and their systems. However, on the whole, there are still problems such as insufficient market share of high-efficiency and energy-saving motors, low energy efficiency of existing motors and their systems, and the potential for the renewal and transformation of motors and their systems is greater. At the same time, a large number of old and inefficient motors in China are facing retirement or elimination every year, and it is of great significance to improve the recycling system of waste motors, improve the level of recycling of renewable resources, and standardize and orderly develop the remanufacturing of waste motors, which is of great significance for smoothing the circulation of the industrial chain and promoting the high-quality development of motors and related industries.

By 2025, the proportion of high-efficiency and energy-saving motors in operation that have reached the energy-saving level (energy efficiency level 2) and above will increase by more than 5 percentage points compared with 2021, and the proportion of new high-efficiency and energy-saving motors in that year will increase by 15 percentage points compared with 2021, achieving annual power savings of about 60 billion kilowatt hours, equivalent to annual energy saving of about 18 million tons of standard coal, and annual carbon dioxide emission reduction of about 35 million 60,000 tons. The R&D level of advanced energy-saving and carbon-reduction technologies and the supply capacity of high-efficiency and energy-saving motors in the motor industry have been effectively improved, and the recycling system of waste motors has been improved.

(1) Continue to improve the supply capacity of high-efficiency and energy-saving motors. Encourage motor manufacturers to improve the energy efficiency level of motors through innovative designs such as motor performance optimization, high efficiency of iron cores, and lightweight motors. Accelerate technological innovation and upgrading, and improve the green level of key supporting materials for high-efficiency and energy-saving motors, such as high-performance magnet wire, high-magnetic inductance and low-loss cold-rolled silicon steel sheet, light rare earth permanent magnet, water-based insulating paint and anti-rust paint, and low-volatile solvent-free impregnating paint. Accelerate the promotion of stator sinusoidal winding, rotor punching groove cutting air gap, rotor low-pressure cast aluminum, rotor high-pressure cast copper, rotor closed groove and other processes, and improve the production guarantee capacity of high-efficiency and energy-saving motors. Accelerate the application of stator and rotor punching progressive die high-speed punching, automatic swing punching, automatic press-fitting, automatic painting, automatic winding and embedding equipment, and improve the automation level of motor production. Encourage motor manufacturers and fans, pumps, compressors and other load equipment manufacturers to strengthen cooperation, combined with the end use of the motor to carry out collaborative design, strengthen upstream and downstream technology matching, and improve the energy efficiency level of the motor system.

(2) Orderly implementation of energy-saving and carbon-reduction transformation of motors in operation. Promote relevant enterprises and units in key industries such as electric power, iron and steel, nonferrous metals, petrochemicals, chemicals, building materials, and textiles to carry out energy-saving diagnosis of motors and their systems in operation, and check the energy efficiency level and operation and maintenance of equipment. Encourage the use of frequency conversion speed regulation, permanent magnet direct drive, industrial servo and motor and drag equipment operating conditions matching technology, focusing on the energy efficiency of the motor below the access level (energy efficiency level 3) to implement the update, fan, pump, compressor and other load equipment to carry out matching energy saving and carbon reduction transformation and operation control optimization. Promote the application of high-efficiency and energy-saving motors, and guide enterprises to actively adopt electrical equipment with energy efficiency reaching the energy-saving level (energy efficiency level 2) and above. Promote enterprises to combine the load characteristics, different working conditions, processes, etc., and apply high-efficiency asynchronous motors, synchronous reluctance motors, variable frequency speed-regulated permanent magnet motors, low-speed direct-drive motors, high-speed direct-drive motors, industrial servo motors and other high-efficiency and energy-saving motors. Encourage enterprises to apply new technologies such as high-power motors and their system status monitoring, remote operation and maintenance, etc.

(3) Phasing out inefficient and backward motors. Strictly implement mandatory national standards such as "Motor Energy Efficiency Limit Values and Energy Efficiency Grades" (GB 18613), "Energy Efficiency Limits and Energy Efficiency Grades of Permanent Magnet Synchronous Motors" (GB 30253), and "Energy Efficiency Limits and Energy Efficiency Grades of High-voltage Three-phase Cage Asynchronous Motors" (GB 30254), and prohibit the production and sale of motors with energy efficiency levels lower than energy efficiency level 3. Implement the relevant requirements of the "Advanced Level of Energy Efficiency, Energy Conservation Level and Access Level of Key Energy-using Products and Equipment (2022 Edition)", strictly implement the energy-saving review of fixed asset investment projects, and enterprises shall not purchase and use motors with energy efficiency lower than the access level for new construction, reconstruction and expansion projects; New projects with an annual energy consumption of 10,000 tons of standard coal and above, as well as projects supported by financial funds such as investment from the central budget, shall not purchase and use motors with energy efficiency lower than the energy-saving level in principle, and give priority to the purchase and use of motors with advanced energy efficiency.

(4) Continuously strengthen the research and development and application of cutting-edge technologies. Strengthen the energy-saving and carbon-reduction technology research of motor bodies, control devices, fans, pumps, compressors and other load equipment systems. Promote the development of technical specifications for energy-saving and carbon-reduction transformation of motor systems under different working conditions. Optimize the motor control algorithm and control performance, and accelerate the breakthrough of technologies such as optimal control of permanent magnet motor efficiency and accurate identification of reluctance motor parameters without position sensor. Carry out research on the specialization of motors with subdivided load characteristics and different working conditions, and accelerate the development of ultra-low-speed motors for direct drive, ultra-high-speed motors, special motors for electric energy replacement in traditional industries, and special motors for the electrification of hydraulic and pneumatic systems. Combined with the operation needs of ports, mines, textiles, building materials, large-scale water conservancy and irrigation and other fields, 8 develop special motors with effective matching of structure and performance.

Fourth, standardize the recycling of waste motors, and accelerate the smooth circulation of the industrial chain

(1) Smooth recycling and disposal of waste motors. Encourage motor users to standardize the motor scrap disposal process in accordance with the relevant regulations on asset management, clarify the motor scrap identification standards, carry out the scrap appraisal of retired equipment in a timely manner, and improve the disposal efficiency of scrapped assets. Vehicle motors should be dismantled or remanufactured in strict accordance with the formal automobile scrapping procedures. To engage in renewable resource recycling business activities, it is necessary to complete the filing of renewable resource recycling operators in accordance with the relevant requirements of the "Measures for the Management of Renewable Resource Recycling". Enterprises that recycle productive scrap metal shall establish a registration system for the recycling of productive scrap metal, and truthfully register the quantity, specification, and degree of newness of productive scrap metal, and the retention period of registration data shall not be less than two years.

Source: National Development and Reform Commission, Motor Today